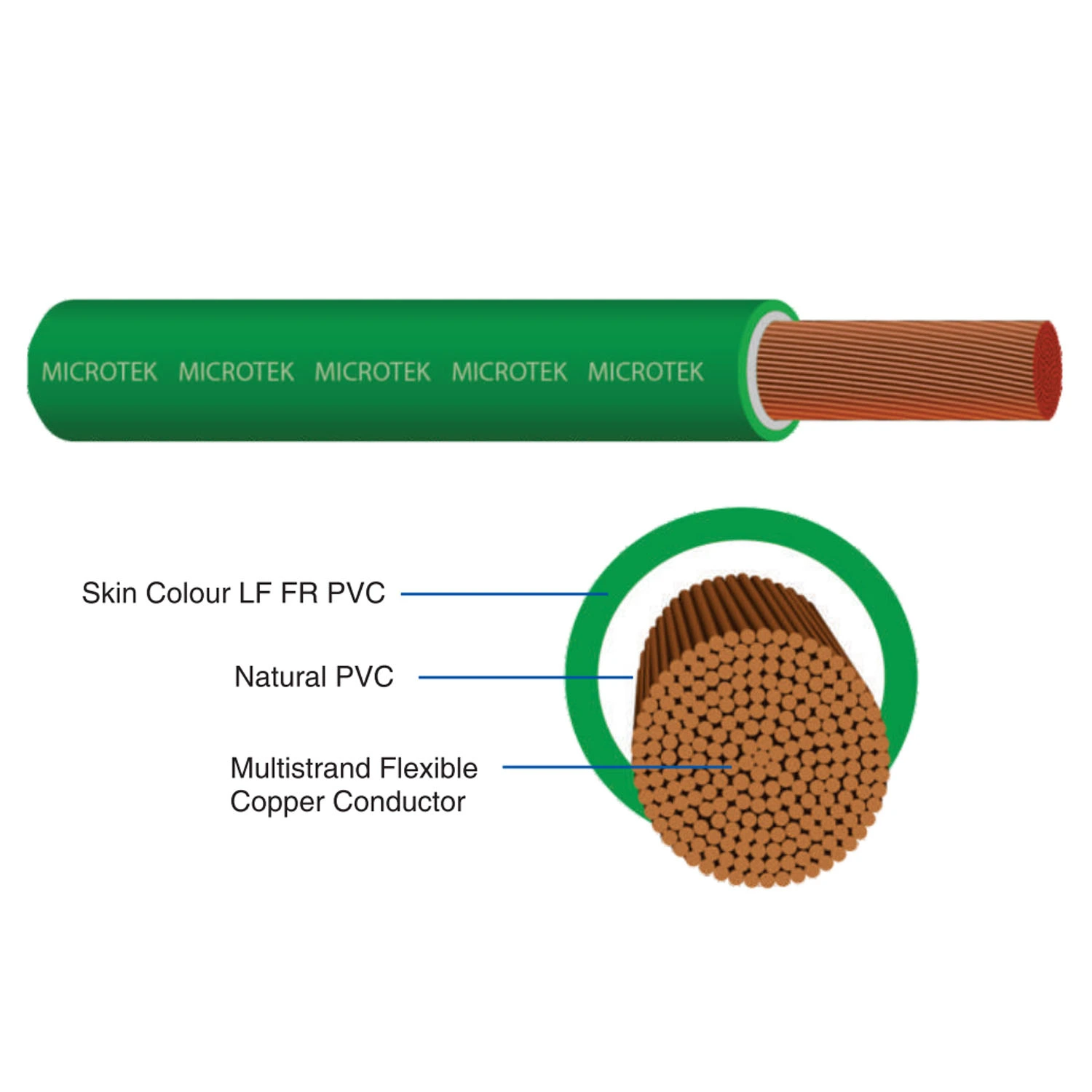

LFFR (LEAD FREE & FLAME RETARDANT) PVC FLEXIBLE WIRE & CABLE

SKU: WIREINQ-00 | Category: Lead Free Flame Retardant Wires

KEY FEATURES

- ENERGY EFFICIENT CABLES

- LOW VOLTAGE DROP

- SHORT-CIRCUIT PROTECTION

- HIGHER Di-ELECTERIC STRENGTH

- HIGHER CONVECTION OF HEAT

- WATERPROOF AND UV RESISTANT